Meggitt Client Case Study (CLF System)

Headquartered in the United Kingdom, this international group operates in North America, Europe and Asia. Known for its specialised extreme environment engineering, Meggitt is a world leader in aerospace, defence and energy. Meggitt employs more than 12,000 people at over 40 manufacturing facilities and regional offices worldwide.

The Requirement

Just over 4 years ago Meggitt launched its dedicated aerospace aftermarket division, Services & Support. Representing a complete portfolio of Meggitt product highlighted an urgent need to integrate group-wide ERP systems and build a central customer led sales forecasting tool. Onepoint was asked to enhance a prototype Customer Led Forecasting tool by building additionalfunctionality.

There was also a need to bolster front-end performance, due to the high volume of data needed by the customer.

A more robust and performant system, capable of swiftly planning and predicting the revenue, budgeting and future sales of all global customers,was required.

The Solution

The Meggitt Customer Led Forecasting (CLF) Application is a sales and production forecasting tooldesigned to accurately predict sales by customer, segment, sales site and/or product type,by processing huge amounts of sales, customer and parts data.

Using a simple SQL server to handle data processing and preparation, MongoDB at the backend and a web-application UI using React and Meteor at the front end, the CLF system groupstogether parts and customers, based on revenue, to reduce the amount of data points that need to be manually predicted. It identifies high revenue customers and low-yielding goods, improving the accuracy of business critical decisions for the sales and operations teams.

The UI web application provides an agile interface to help drill down and aggregate data. With this reactive-view of the data, any changes made to underlying data is immediately reflected in the forecast, so that the sales teamreceives accurate predictions at any given time.

The system is also designed to generate real-time reports comparing plan vs actual.

The Outcome

The Meggitt CLF system is proving to be an invaluable tool for senior management, sales finance and operations teams. It enablesgreater transparency and faster decision making with its ability to provide improved forecasting accuracy based on historic transactions and customer data.

Category

Industry

Solution

ETL, Data Integration and UI

Technology

Service

Meggitt Client Case Study (Lexington)

Headquartered in the United Kingdom, this international group operates in North America, Europe and Asia. Known for its specialised extreme environment engineering, Meggitt is a world leader in aerospace, defence and energy. Meggitt employs more than 12,000 people at over 40 manufacturing facilities and regional offices worldwide.

The Requirement

Meggitt is going through a major transformation, building a new organisation better aligned to its markets and customer operations. Services & Support, its dedicated aftermarket organisation, was initially established at the start of this transformation programme just over 4 years ago. It has grown rapidly and as the product portfolio has increased it has been necessary to access a variety of ERP systems to gain essential management data. Using a variety of systems requires extensive manual processing and increases the potential for data quality errors.As a distribution company, transparent inventory levels and fast transactions are essential for stock management, customer satisfaction and growth.

To create the transparency required and enable fact based decision making, integration was essential.

Meggitt chose to use an Azure based platform to combine its three main operational ERP systems, providing accurate, consolidated data in real time.

The Solution

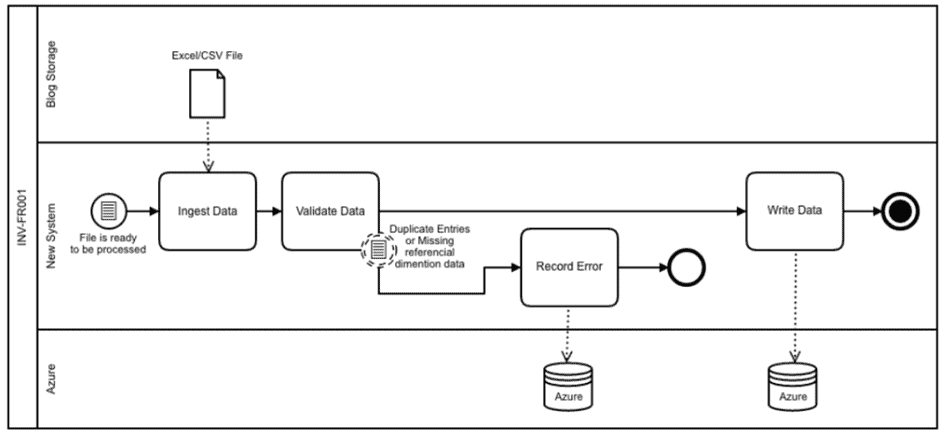

The new system is hosted in Azure and uses Azure integration tools. Azure Blob Storage and Azure Data Factory are used to ingest input files, and Azure SQL server (managed cloud database) is used for reporting purposes to create fact and dimension tables.

It’s a simple but effective process:

- Ingest files

- Ingest daily CSV flat files from the 3 ERP Systems.

- Ingest manually maintained excel files to update dimension tables

- Validate data

- If duplicate keys or missing reference dimension data is found in the same file, then an error is registered and sent.

- Daily email notification

- Daily email notifications are sent when duplicate keys are found in a specific file, or when reference dimension data is missing.

- Produce cube

Produce cubes/views for the fact tables with additional lookup and calculated fields.

Figure 1

The Outcome

Meggitt now has much improved quality and transparency of data, enabling swift decision making and greater inventory control. The slim-line process has improved customer service and efficiency levels exponentially.

Category

Industry

Solution

ETL, Data Integration